A few weeks ago, just before the buzz and bustle of Watches & Wonders, I found myself climbing the confined staircase of a double-decker tour bus. I come to Geneva a couple of days early thanks to an invite from Tudor offering a tour of the brand's newly-opened facility in Le Locle, Switzerland. Not one to turn down such an invite – not to mention a recent delivery of a Pelagos 39 that had been assembled in the new facility – the day promised a rare glimpse inside the often secretive but evolving world of Tudor. Checking the time on that very same watch, I watch from the upper deck as other members of the watch press filed out of the hotel and found a seat on the bus.

The drive from Geneva to the new Tudor facility should take about two hours as we roll out of the city on the lake and head into Le Locle, one of the main centers of watchmaking for the entire Swiss industry. Interestingly, despite having been around for some 97 years, this is Tudor's first exclusive production site. Construction began in 2018 and the building was completed in 2021, offering Tudor a specialized home in the ideal area to connect with suppliers, industrial capability, and – crucially – trained watchmakers.

The total building is over 114,000 sqft and offers more than 60,000 sqft of workspace for the assembly, testing, and quality control of Tudor's watches, which number more than 700 references and are sold in 80 countries around the world. From an engineering standpoint, the building represents a fully modern and entirely considered solution, complete with a specialized HVAC system to provide ideal control over temperature and humidity, self-tinting electrochromic windows, and some 442 solar panels to help power the whole operation.

Divided into two logical parts, one element of the new facility is dedicated to Tudor's operations, including the assembly floor, the testing floor, and quality control (including component checks, bracelet fitting, and engraving). The other side of the facility is dedicated to Kenissi, Tudor's movement manufacturing outfit.

We start at the movement side of the new facility with Kenissi.

Watchmakers at work assembling Tudor movements.

For those that have never found it all that clear, Kenissi was founded and is owned by Tudor. The result of Tudor's work in creating their own movement back in 2015, Kenissi was launched in 2016 as a subsidiary of Tudor that manufactures and assembles movement not only for Tudor (duh), but also Chanel (who owns a piece of the Kenissi business), Breitling, TAG Heuer, Norqain, and others. That being said, Kenissi is Tudor.

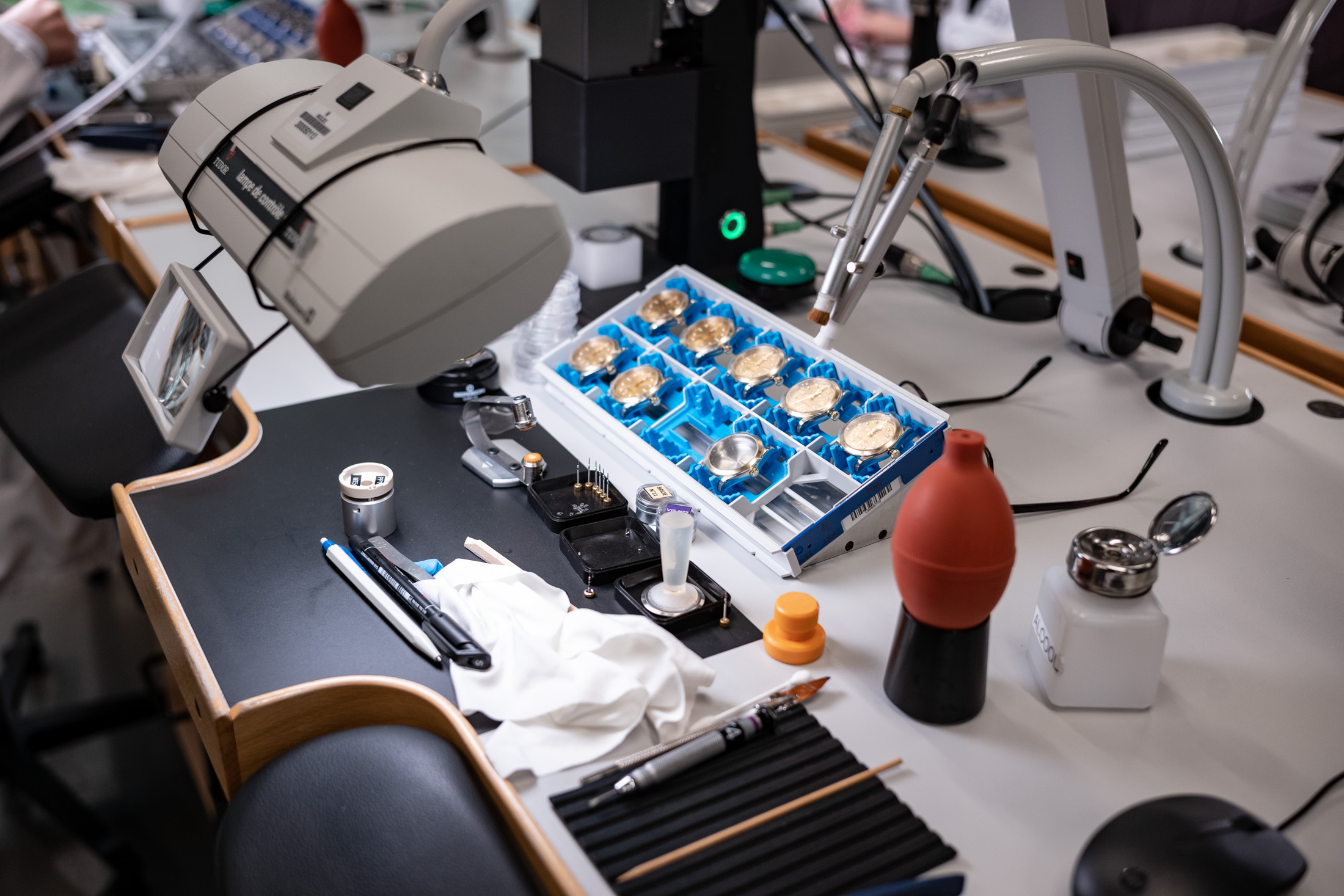

A watchmaker sits at their desk, which includes a tiny built-in production that manages movements throughout the hand assembly process. A movement is delivered to the watchmaker, they do their work, and it then rejoins the cue flowing through the desks from a centralized storage hub that is supported by a robotic arm.

Kenissi manufactures movements that fall into one of three families and the company currently produces about 80% of the components for a given movement (with the rest being supplied via close partners). The new Tudor facility offers a pair of identical assembly lines that feed components, and, after hand-assembly, final movements to a series of stops along a largely automated line. Interestingly, where Kenissi is vertically integrated, Tudor's non-movement production is much more horizontally integrated as the various components are produced either via brand partners or through ancillary companies that Tudor owns in Switzerland.

Movements are delivered via a specialized system of tunnels that connect each desk with each stage of the movement assembly.

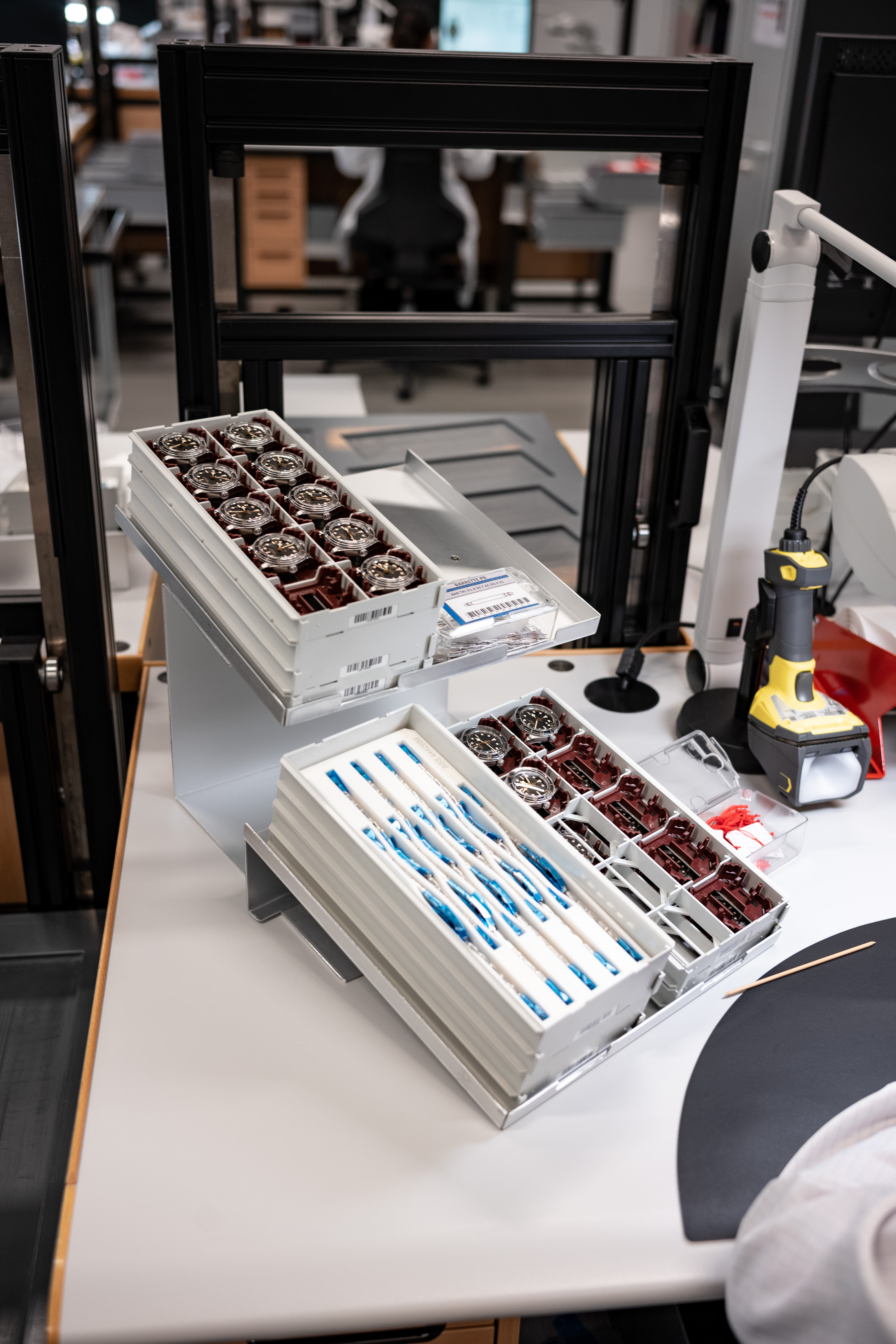

Tiny movements in plastic holders flow through translucent tunnels, in and out of the hands of watchmakers, all controlled by computers and specialized processes. When the movement is ready, it heads to the other side of the building, where it is installed into a Tudor watch on the assembly floor.

The assembly floor feels a lot like other watch manufacturers I've visited. Groups of nested watchmaking workspaces allow the various components of the watch to come together via the hands of a skilled watchmaker. Each cell of desks is capable of assembling and checking any reference and the entire process operates on a "no stock" philosophy, so production is based on actual demand from clients and retailers. Brand new air circulates through 3.5 times per hour and the flow of the air in the space has been specifically designed to keep dust to an absolute minimum.

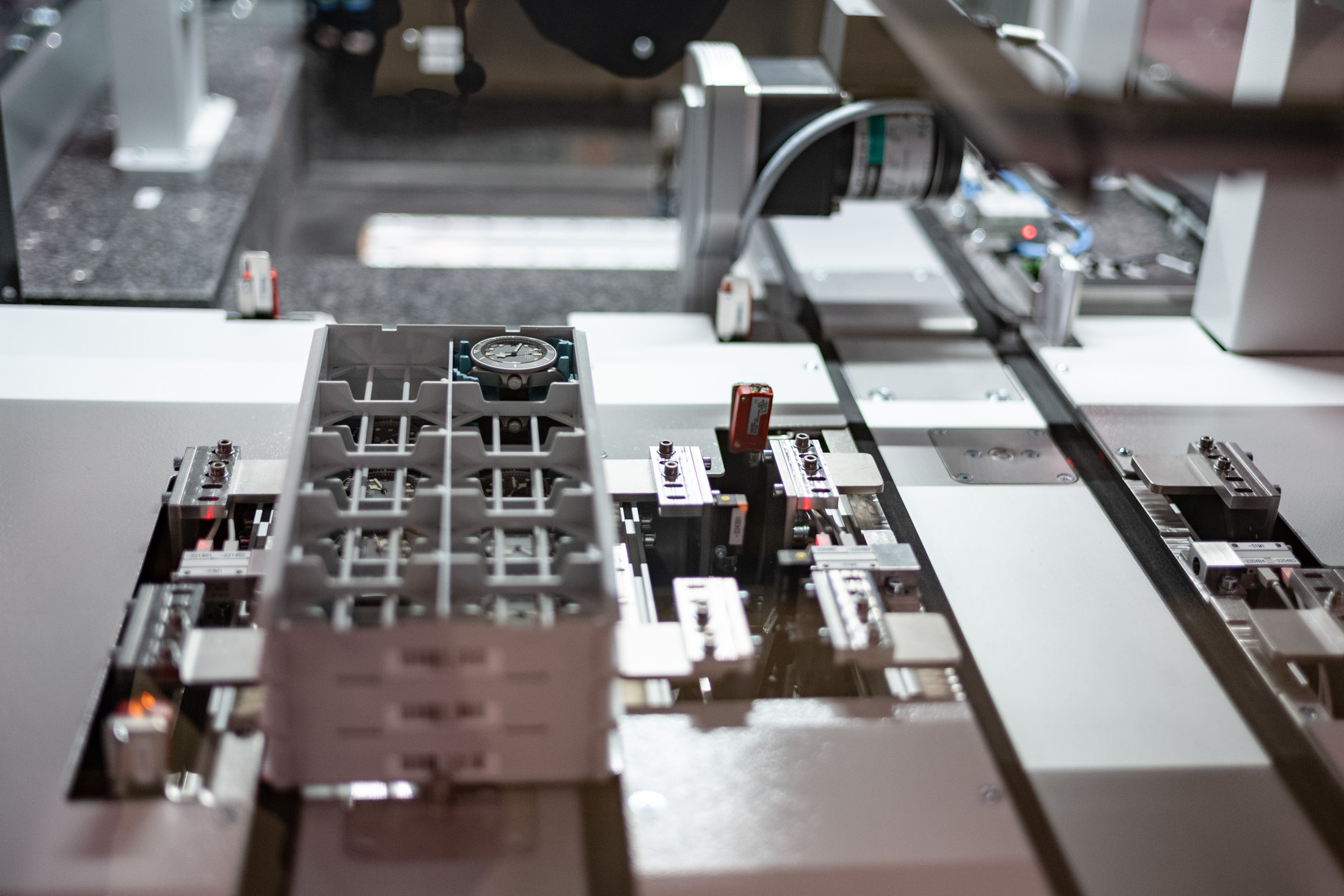

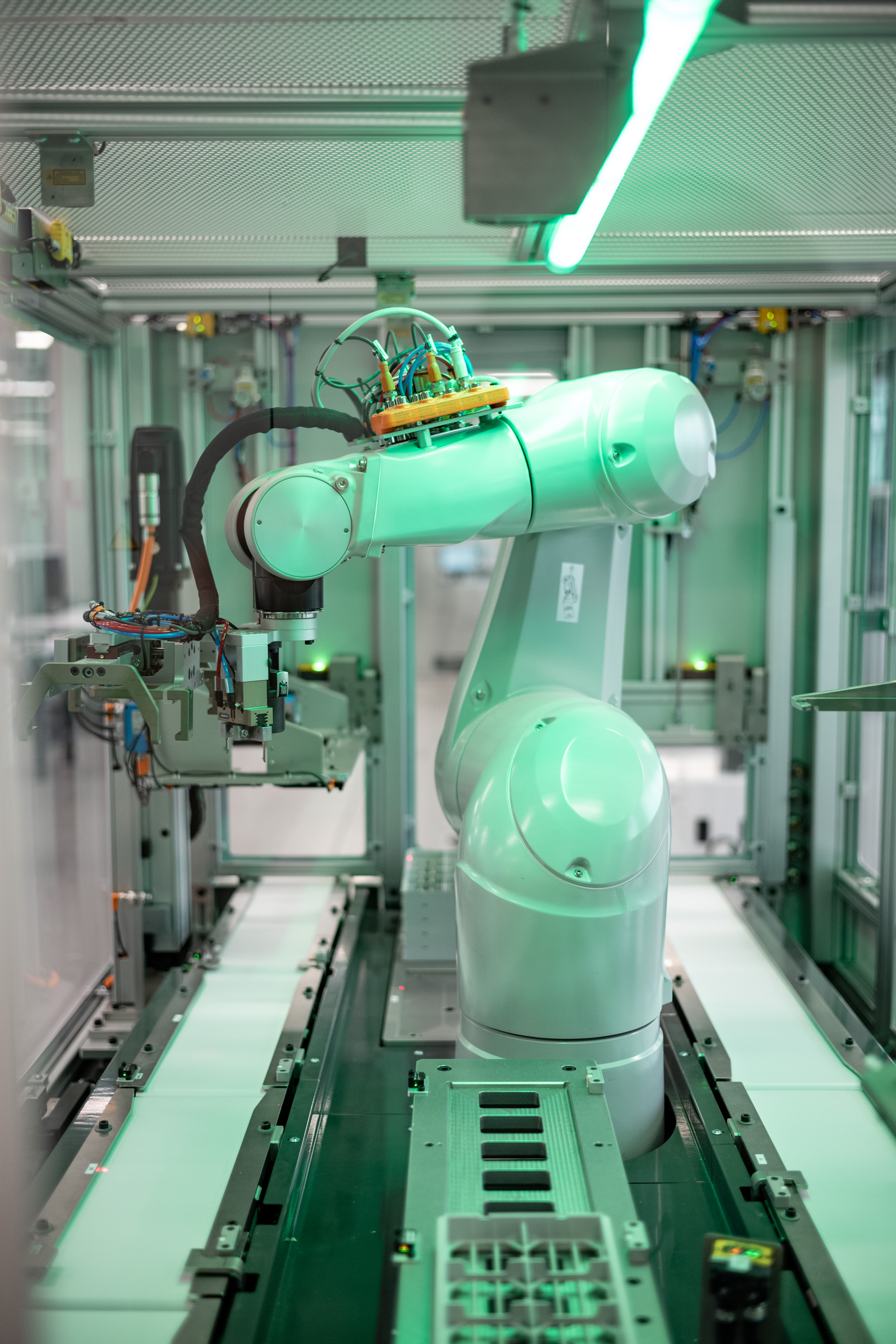

The next stop is the testing floor, in which partially assembled watches (no strap or bracelet) are subjected to a battery of tests that pertain to either METAS or TPC (that's Tudor Performance Control) stipulations. This area is fully autonomous, running 24 hours a day with the support of some very cool robots. The watches are pressure tested, checked for precision, subjected to extreme magnetism (especially for the METAS certification), and are even tested for the proper functioning of the power reserve. Can you spot some of the interesting models we saw mid-testing?

Robots, be they arms or sort of Dalek-like delivery bots make up an interesting portion of this stage, and it's neat to experience the cross-section of modern manufacturing processes against the backdrop and environment of Swiss watchmaking.

A specialized robot delivers a tray of Black Bay Ceramic models to a collection area.

This is the testing floors anti-magnetism rig, which is capable of testing a group of METAS chronometers up to 15,000 gauss.

The special tray that carries the METAS Chronometers into the anti-magnetic testing machine.

Finally, the watches reach the last stop, where a group of watchmakers completes a full check of the watch and its functions, coordinates any request for engraving, and fit the bracelet or given strap. Interestingly, the engraving is laser-based and you can actually do some pretty wild designs...

This caseback is not wearing hockey pants.

After seeing so many robotic arms carrying out specific processes, it was fun to see a real human fit a fresh bracelet in just a few seconds. I wish they had been offering classes as it takes a special touch to fit a Tudor bracelet without causing any scratches (and let alone doing it with a complete bracelet that is also wrapped in plastic for delivery). Really cool.

Fitting bracelets and other straps.

Look, if you know me and what I love to write about, you'll know that I've offered a lot of praise to Tudor over the past decade. I enjoy the watches that they produce and have even put my money where my mouth is with the recent purchase of a Pelagos 39. As such, it was a special treat to get a tour of the Le Locle facility and to meet some of the people that are actually assembling their watches. My watch, even.

Getting back on the bus to head back down to Geneva, the new Tudor facility underlined one major concept for me – maturity. While I don't think there is anyone out there claiming that Tudor should keep its distance from Rolex, it's clear that Tudor has been incredibly successful over the past 15 years and that success has afforded the brand a bit of breathing room. That independence could signal many things.

Perhaps that means increased production, and it almost certainly means a continued push toward more METAS Chronometers in the lineup. But it also means that Tudor can protect its price point, its production, and its supply chain in a manner that sets the brand up for continued success, especially when it comes to actually getting Tudor watches on the wrists all over the world.

Bagikan Berita Ini

0 Response to "Inside The Manufacture: A Tour Of Tudor's New Manufacture In Le Locle - HODINKEE"

Post a Comment