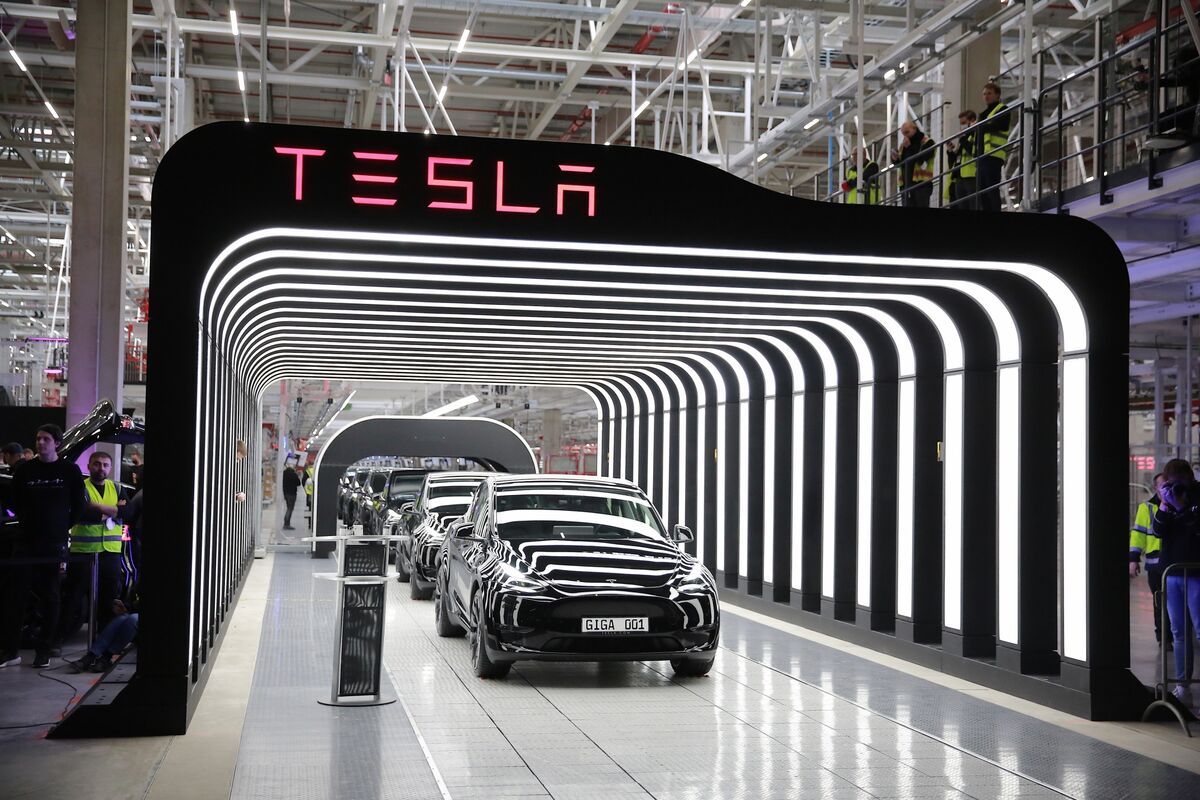

Tesla Inc. has a plan to fend off cheaper competition from China with a $25,000 electric car. But first it has to overhaul a 100-year-old manufacturing process pioneered by Henry Ford.

The company is moving to what it calls an “unboxed” approach, which is more like building Legos than a traditional production line. Instead of a large, rectangular car moving along a linear conveyer belt, parts are assembled simultaneously in dedicated areas and then all put together at the end. Tesla says the change could reduce manufacturing footprints by more than 40%, allowing the carmaker to build future plants far faster and at less expense.

Read Again https://news.google.com/rss/articles/CBMidmh0dHBzOi8vd3d3LmJsb29tYmVyZy5jb20vbmV3cy9hcnRpY2xlcy8yMDI0LTAzLTI4L3Rlc2xhLXMtdHNsYS1uZXctdW5ib3hlZC1tYW51ZmFjdHVyaW5nLXByb2Nlc3MtYWltcy10by1jdXQtY29zdHMtNTDSAQA?oc=5Bagikan Berita Ini

0 Response to "Tesla's (TSLA) New Unboxed Manufacturing Process Aims to Cut Costs 50% - Bloomberg"

Post a Comment